A temporary strainer is a filtration device installed in pipelines for short-term use during the commissioning phase. Designed to trap debris and particles, it prevents damage to downstream equipment such as pumps, valves, and membranes.

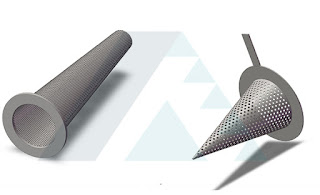

Temporary strainers come in various configurations, including cone strainers, basket strainers, and Y-strainers, each suited for specific operational needs.

In desalination plants, where pipelines carry seawater laden with particulates, these temporary strainers are essential to maintain system integrity and prevent costly downtime.

Applications in Seawater Desalination Pipelines

Seawater desalination involves transforming saline water into potable water through reverse osmosis (RO) or thermal distillation. The pipelines in these systems transport large volumes of water, making them prone to debris accumulation during installation and commissioning. A temporary strainer for desalination pipelines ensures:

- Debris Removal: By capturing sand, welding slag, and construction residue, strainers protect critical components like RO membranes.

- Pipeline Protection: Prevents clogging and damage to expensive infrastructure.

- Efficient Commissioning: Ensures a smooth startup by reducing the risk of operational delays caused by blockages.

- Cost Savings: Minimizes repair and maintenance costs associated with debris-induced wear and tear.

Application Case

We delivered a batch of temporary filters to Saudi Arabia this year for desalination plants. The custom design was well received by customers! The second batch of temporary filter purchase orders will be completed by the end of the year!

Benefits of Using Temporary Strainers in Desalination

- Corrosion Resistance: Made from stainless steel or other durable metals, temporary strainers withstand the harsh conditions of seawater environments.

- Customizable Design: Temporary strainers can be tailored to fit specific pipeline dimensions and flow requirements.

- Ease of Maintenance: Designed for quick removal and cleaning, ensuring minimal disruption during commissioning.

- Enhanced Equipment Longevity: By preventing debris from reaching sensitive components, strainers extend the lifespan of critical equipment.

Choosing the Right Temporary Strainer for Desalination Pipeline Commissioning

When selecting a temporary pipeline filter for desalination plants, several factors should be considered:

- Material: Stainless steel is the preferred choice due to its corrosion resistance and durability in saline environments.

- Filtration Level: Determine the required mesh size to capture debris without impeding flow.

- Flow Capacity: Ensure the strainer can handle the pipeline’s flow rate without significant pressure drop.

- Ease of Installation: Choose a design that integrates seamlessly into the pipeline.

By choosing the right type of temporary strainer and adhering to proper installation and maintenance practices, desalination plants can achieve reliable performance during commissioning and beyond.

Our temporary strainers are the first line of defense in maintaining the integrity of desalination pipelines and ensuring the success of water treatment processes. Contact us Now!

Contact us

Email: sales@yubofilter.com

WhatsApp: 86 13653285589

评论

发表评论