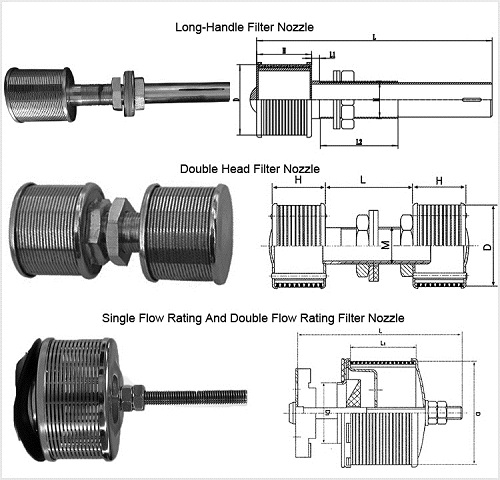

The stainless steel water nozzle is mainly used for the separation of liquid and solid or gas and solid to prevent the loss of filter media (sand, catalyst, resin, silicate, activated carbon, etc.). It is usually used as a collector and distributor for desalination devices, water softeners, and pressure and gravity sand filters. In the process of liquid or gas collection or distribution, the number and distribution of water caps are designed to achieve a specific flow rate.

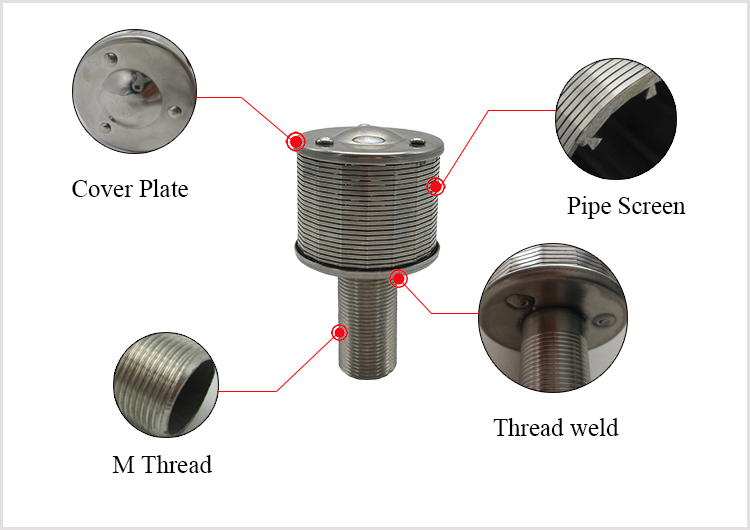

The water nozzle consists of a pedestal, a cover plate, a trapezoidal screen with ribs and a diversion tube. The central axis of the trapezoidal screen is provided with a flow-through valve cup that is inverted and fixed to the pedestal. The lower opening contains the part of the flow-guide tube that extends into the pedestal. The bottom, wall and flow-guide tube of the flow-through valve cup are contained. The upper pipe wall is provided with a plurality of pores, and a flow-through valve core that can float up and down is provided on the top of the draft tube. By setting the flow rate of the trapezoidal screen, the number of round holes, the size of the pore size and the gap distance, the water cap can meet the various flow rate ratios of the backwash and filtered water flow rates under different process conditions.

Material: AISI304, AISI304L, AISI316, AISI316L, Superdulex 2507, Hastelloy, etc.

Features:

1. Large flow area,

2. Free from influence of temperature

3. Corrosion resistance

4. Anti-aging and long service life

5. Easy replacement

6. Safe and reliable

Applications

Power plants, petroleum, chemical, pharmaceutical, food and beverage, etc.

WhatsApp/skype: +86 136 5328 5589

WeChat: +86 173 6301 0656

评论

发表评论